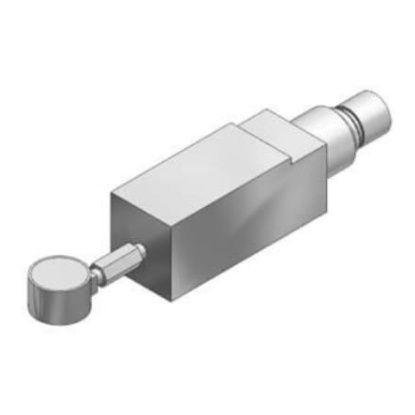

Pneumatic Regulators

Pneumatic regulators, also referred to as pressure-reducing valves, are utilized in pneumatic systems to maintain consistent output air pressure. They are frequently applied in pneumatic air compressors.

Pneumatic regulators offer fast response times and precise pressure control for demanding industrial air preparation tasks, ensuring that compressed air within a pneumatic system is efficiently used without waste.

How Does a Pneumatic Regulator Operate?

Pneumatic regulators play a vital role in maintaining output pressure by automatically stopping the flow of gas or liquid once a preset pressure is reached. Most models rely on simple wire coil springs to manage pressure control effectively.

When installing a pressure regulator, it is important to choose one that matches your system and pneumatic fittings properly. Selecting a regulator that is too large can cause unnecessary air consumption and energy loss. Therefore, proper sizing is key to achieving optimal performance and efficiency.

Types of Pneumatic Regulators

Pneumatic regulators are available in various types, each tailored for specific applications and requirements. Some common types include:

- General-purpose regulators: Versatile units suitable for a broad range of uses, offering dependable performance at a reasonable cost.

- Precision regulators: Designed for applications requiring exact pressure control, providing high accuracy and stability, such as in oxygen ventilators.

- Filter regulators: Also known as air preparation units, these combine pressure regulation with filtration to remove impurities and moisture, protecting downstream equipment and ensuring air quality.

- Relieving regulators: Automatically vent excess pressure above a set threshold to protect equipment and prevent damage during overpressure situations.

- Non-relieving regulators: Lack a pressure relief function and are used where overpressure risk is low or a separate relief valve exists elsewhere in the system.

Why is Precise Pressure Control Vital in Pneumatic Systems?

Accurate pressure control is essential in pneumatic systems for optimal performance, safety, and energy efficiency.

- Consistent performance: Keeping pressure stable ensures reliable operation of pneumatic equipment, producing predictable results and reducing downtime.

- Prevention of equipment damage: Avoiding overpressure or fluctuations protects sensitive components from costly damage.

- Enhanced safety: Managing pressure levels reduces risks of system failure or injury due to overpressure.

- Energy efficiency: Maintaining correct pressure reduces compressed air consumption and lowers operating costs.

- Improved product quality: Stable pressure control supports consistent operation of pneumatic tools, enhancing manufacturing outcomes.

- Extended system life: Proper pressure management decreases wear and tear, prolonging equipment lifespan.

Common Applications of Pneumatic Pressure Regulators

Pneumatic regulators are widely used in various residential and industrial settings, including heating furnaces, gas grills, medical devices, and dental equipment. They are particularly valuable in applications requiring tight pressure control, such as gas handling.

Pneumatic Regulator vs. Pressure Relief Valve

Although both pneumatic regulators and pressure relief valves are important in pneumatic systems, they serve different purposes and operate distinctively.

- Function: Regulators maintain consistent output pressure for optimal equipment operation, while relief valves protect against overpressure by releasing excess pressure.

- Operation: Regulators constantly monitor and adjust pressure to a setpoint; relief valves remain closed until pressure surpasses a safety threshold.

- Use: Regulators ensure controlled pressure delivery; relief valves act as safety devices to prevent damage.

- Design: Regulators consist of a valve body, diaphragm, and spring; relief valves feature a spring-loaded valve that opens when pressure is too high.

- Pressure control: Regulators allow precise, adjustable pressure settings; relief valves provide basic overpressure protection.

- System impact: Regulators directly influence system pressure; relief valves serve as emergency safeguards.

Key Factors When Selecting an Air Compressor Regulator

- Inlet pressure: Confirm the regulator is rated for your system’s maximum inlet pressure.

- Outlet pressure: Ensure the regulator can supply the desired pressure range to your equipment.

- Connection port sizes: Match port sizes to your system’s piping to avoid leaks or flow issues.

- Flow rate: Select a regulator with sufficient capacity to meet your equipment’s air demand.

- Operating temperature: Choose a regulator capable of functioning reliably within your system’