Pneumatic Clamping Cylinders

Pneumatic clamping cylinders are devices designed to hold or secure materials and equipment during operations. These clamps are especially useful for rapid clamping in production environments, ensuring the actuator rod remains fixed in a vertical position to prevent unintended retraction—an important safety feature for operators.

They rely on spring-based mechanisms that are held open by compressed air. In the event of a pressure drop—due to a leak, for example—the clamp automatically engages, locking the rod in place until system pressure is restored. Mounting options vary and typically include through-hole and tapped mounting styles.

At Pneumatic Resources, we offer a wide selection of pneumatic clamping cylinders with bore sizes ranging from 12 mm to 63 mm. Our models feature corrosion-resistant clamping arms and are built to handle a variety of clamping requirements efficiently.

Applications of Clamping Cylinders

These cylinders use air-driven mechanisms to initiate clamping, making them suitable for securing items during repairs or material handling processes. They are widely used in robotic systems and automated workflows, particularly in the automotive and industrial manufacturing sectors.

Types of Pneumatic Clamping Cylinders

Pneumatic cylinders function by converting compressed air energy into linear motion. Clamping variants are available in several forms to meet specific operational needs, including:

- Rotary clamping actuators: Utilize lubricated compressed air and feature clamping arms to hold materials securely.

- Pancake clamping actuators: Compact and space-efficient, these units can function with either lubricated or dry air.

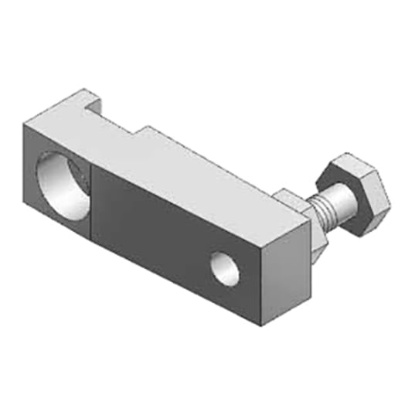

- Pin clamping actuators: Offer both precise positioning and secure clamping through integrated guide pins.